aleatorylamp

Charter Member

Hi all, and Hi Ivan!

I have started this new thread for the Curtiss Wright At-9 "Jeep" I have under construction. It was also called "Fledgeling", and the manufacturer´s number was CW25.

The model is available here for anyone to look at, try out and if possible, comment on and maybe even cooperate with:

http://www.sim-outhouse.com/sohforum...id=19&id=19844

My idea is not only to facilitate questions and answers regarding the progress of this WIP - work in progress - open on its own thread, but possibly also issue an invitation to anyone wishing to cooperate.

In fact, it could be maybe even a joint hobby venture, if you like!

At the moment, the model is roughly at 75%.

- There is neither a hollow, transparent cabin, nor instructor and student pilot.

- I´m still curing little bleedthroughs and gaps between parts in certain places.

- Because of moving control surfaces, perhaps other groupings are more effective, but cause bleedthrough elsewhere, specially in the tail.

-Textures are a bit simplistic as yet, and I need more expertise.

-The greatest problem is the flight dynamics - the FS98 FD work great! ...not so the CFS1 ones.

CFS1 FD:

It must have been quite a handfull for pilots, and the FD are by no means correct.

I have found comments like:

-I had great fun doing acrobatics.

-A quick snap of the yoke could generate a high speed stall.

-Approach and landing: Always maintain air speed=110-120mph!

-On power off landings you viewed the air strip through the upper window!

-A dead stick landing was done at a 45 degree angle as there was little if any gliding ratio.

-One told of losing an engine and barely making it back to the field, ruining the good engine in the process.

-They wouldn't fly on one engine.

-Full flaps were never set as speed went down too far, risking stall.

The Propeller (tables 511 and 512):

I´m trying to adjust the CV prop for the AT-9 Jeep. As the engines are 295 Hp radials, presumably non-supercharged, I´m having difficulty in adjusting the props to the engines.

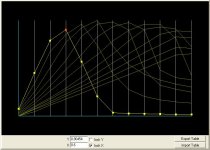

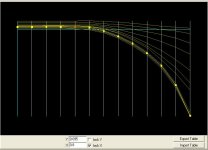

I managed to make AAM work on my computer, by putting it into the C: directory, and the visual display of the propeller graphs seems more meaningful than the numbers in AirEd.

All stock aircraft have really strong, large multi-cylinder engines, above 1000 hp, and the propeller graphs (511 and 512) appear to be the same for all, there being no example for a 300 hp engine.

My experience on tables 511 and 512 is reduced to the 25 degree column for fixed pitch props, and as I was getting about 90 hp after putting in the engine details, I patiently lowered all the propeller thrust and efficiency graphs, and I got upp to 230 or 240 hp, but to get the required power, I had to put the torque graph up to 85 and reduce the friction to 36, which is not really correct, I believe.

I´ve managed to get top speed correct, but accelleration is very slow, and as soon as a climb is started, speed falls off very quickly.

Also, ailerons and turning are sluggish - not so on the FS98 FD!

So the bottom line is, I would indeed appreciate some help and guidance!

Cheers,

Aleatorylamp

I have started this new thread for the Curtiss Wright At-9 "Jeep" I have under construction. It was also called "Fledgeling", and the manufacturer´s number was CW25.

The model is available here for anyone to look at, try out and if possible, comment on and maybe even cooperate with:

http://www.sim-outhouse.com/sohforum...id=19&id=19844

My idea is not only to facilitate questions and answers regarding the progress of this WIP - work in progress - open on its own thread, but possibly also issue an invitation to anyone wishing to cooperate.

In fact, it could be maybe even a joint hobby venture, if you like!

At the moment, the model is roughly at 75%.

- There is neither a hollow, transparent cabin, nor instructor and student pilot.

- I´m still curing little bleedthroughs and gaps between parts in certain places.

- Because of moving control surfaces, perhaps other groupings are more effective, but cause bleedthrough elsewhere, specially in the tail.

-Textures are a bit simplistic as yet, and I need more expertise.

-The greatest problem is the flight dynamics - the FS98 FD work great! ...not so the CFS1 ones.

CFS1 FD:

It must have been quite a handfull for pilots, and the FD are by no means correct.

I have found comments like:

-I had great fun doing acrobatics.

-A quick snap of the yoke could generate a high speed stall.

-Approach and landing: Always maintain air speed=110-120mph!

-On power off landings you viewed the air strip through the upper window!

-A dead stick landing was done at a 45 degree angle as there was little if any gliding ratio.

-One told of losing an engine and barely making it back to the field, ruining the good engine in the process.

-They wouldn't fly on one engine.

-Full flaps were never set as speed went down too far, risking stall.

The Propeller (tables 511 and 512):

I´m trying to adjust the CV prop for the AT-9 Jeep. As the engines are 295 Hp radials, presumably non-supercharged, I´m having difficulty in adjusting the props to the engines.

I managed to make AAM work on my computer, by putting it into the C: directory, and the visual display of the propeller graphs seems more meaningful than the numbers in AirEd.

All stock aircraft have really strong, large multi-cylinder engines, above 1000 hp, and the propeller graphs (511 and 512) appear to be the same for all, there being no example for a 300 hp engine.

My experience on tables 511 and 512 is reduced to the 25 degree column for fixed pitch props, and as I was getting about 90 hp after putting in the engine details, I patiently lowered all the propeller thrust and efficiency graphs, and I got upp to 230 or 240 hp, but to get the required power, I had to put the torque graph up to 85 and reduce the friction to 36, which is not really correct, I believe.

I´ve managed to get top speed correct, but accelleration is very slow, and as soon as a climb is started, speed falls off very quickly.

Also, ailerons and turning are sluggish - not so on the FS98 FD!

So the bottom line is, I would indeed appreciate some help and guidance!

Cheers,

Aleatorylamp