You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

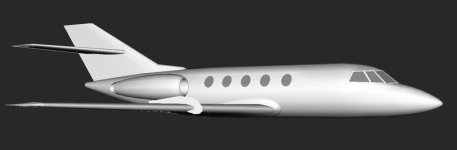

I have done som knitting :-)

- Thread starter rotorhub

- Start date

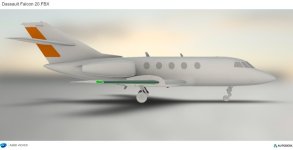

gmax finally working in win 10

I have successfully exported my mesh from AC3D to gmax. I have tested UV maps from AC3D to gmax and assigned FSX10 materials. Then the FSX MDL was converted to DirectX in MCX and exported to P3D V3 SDK without problems.

Everything seems to work, and simple animations have been tested. Finally I can get started with gmax and perhaps I can get the Falcon 20 flying with animations. Perhaps...

rotorhub

I have successfully exported my mesh from AC3D to gmax. I have tested UV maps from AC3D to gmax and assigned FSX10 materials. Then the FSX MDL was converted to DirectX in MCX and exported to P3D V3 SDK without problems.

Everything seems to work, and simple animations have been tested. Finally I can get started with gmax and perhaps I can get the Falcon 20 flying with animations. Perhaps...

rotorhub

Attachments

That is looking great Sir!!!

Wow! What acrobatics you went through

Wow! What acrobatics you went through

Yes Milton, I know  I hope to learn to knit in gmax as well. AC3D is very easy to use polybending software, with few tools and no animation functionality. Except for X-Plane. However it supports a lot of formats. ModelconverterX is a very powerful tool, not only for scenery designers. I am using it for the Commander conversion. Unfortunatly the Commander will not load in gmax for some reason. I was hoping to bring it over to native FSX format with gmax.

I hope to learn to knit in gmax as well. AC3D is very easy to use polybending software, with few tools and no animation functionality. Except for X-Plane. However it supports a lot of formats. ModelconverterX is a very powerful tool, not only for scenery designers. I am using it for the Commander conversion. Unfortunatly the Commander will not load in gmax for some reason. I was hoping to bring it over to native FSX format with gmax.

Yes Milton, I knowI hope to learn to knit in gmax as well. AC3D is very easy to use polybending software, with few tools and no animation functionality. Except for X-Plane. However it supports a lot of formats. ModelconverterX is a very powerful tool, not only for scenery designers. I am using it for the Commander conversion. Unfortunatly the Commander will not load in gmax for some reason. I was hoping to bring it over to native FSX format with gmax.

Happy to see you making progress on various fronts.

If you want to send me that gmax source, I'll see if I can determine why it will not load.

Hi Milton,

That is very kind of you.

However, I just got it loaded and managed to save it before it crashed. It looks like I can open and save now. I just got an initial error from one of the FSX scripts, but they load fine now.

I must get better aquinted with gmax before I start trying to update the materials and animations.

That is very kind of you.

However, I just got it loaded and managed to save it before it crashed. It looks like I can open and save now. I just got an initial error from one of the FSX scripts, but they load fine now.

I must get better aquinted with gmax before I start trying to update the materials and animations.

Hi Milton,

That is very kind of you.

However, I just got it loaded and managed to save it before it crashed. It looks like I can open and save now. I just got an initial error from one of the FSX scripts, but they load fine now.

I must get better aquinted with gmax before I start trying to update the materials and animations.

Ahhh, great to hear.

You might check out my new video tutorials then. Just click the first link in my signature.

Ahhh, great to hear.

You might check out my new video tutorials then. Just click the first link in my signature.

Yes Milton, I am going over the videos. Thanks for the efforts helping us in the right direction. I am not looking forward to the gear animation though

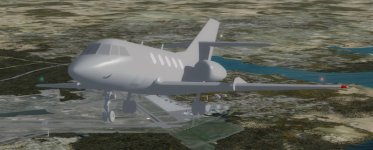

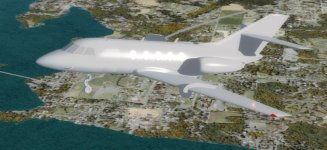

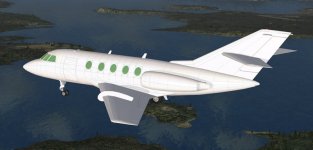

gmax still crashes now and then, but only with the Commander. The Falcon works great but it does not have any animations. The exterior is getting closer to completion.

Attachments

Rotohub,

The model is looking great; so is the gear. You need not fear animations; it's one of the easiest things you will do. See the video; work it top down starting with extend/retract frames 0-100. Then on to oleo compression 100-200. Do the torque links last once you are satisfied with suspension. Remember to give plenty of oleo movement, minimum up/down is tire height, tread to rim, but I usually go about 30-40% of tire diameter depending on aircraft.

For nose gear, do your steering animation last.

The model is looking great; so is the gear. You need not fear animations; it's one of the easiest things you will do. See the video; work it top down starting with extend/retract frames 0-100. Then on to oleo compression 100-200. Do the torque links last once you are satisfied with suspension. Remember to give plenty of oleo movement, minimum up/down is tire height, tread to rim, but I usually go about 30-40% of tire diameter depending on aircraft.

For nose gear, do your steering animation last.

Thanks and noted. I am doing animation trials on very simple objects, and figuring out the tools. I remember reading about the tape measure tool for a long time ago.

Remember that in FSX/P3D texture mapping has to be done before animations ... I think.

Procedure is pretty simple:

1) Start with everything in retracted mode, as if flying. That's frame 0

2) Set Local Coordinate pivot at rotation point of top strut

3) Set Animation Rotation key at KF 0 and position key at KF 100 for the top strut

3) Turn on Animation; Animate extension 0 (retracted) -100 (extended) using Local Coordinate pivot by moving slider to 100 and rotating the top strut to extended position; turn off animation

4) Set position keys for lower strut (oleo) 100-200 (no rotation key needed if standard up/down)

5) With slider at 100, turn on animation; move slider to 200; move oleo up to max compression; turn off animation

6) Test

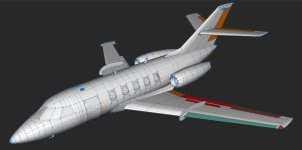

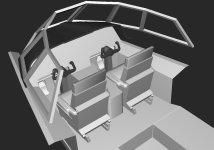

The VC is shaping up nicely Sir

Gear animation

Hi Milton,

Thanks for you input and your tutorials, they are much appreciated. Gmax is great once you get more insight. I have been going trough your gear animation series, and I have done some test runs on basic gear animation. It works

However the Falcon 20 gear is slightly different. I just wondered if I could get som input on the damper pivot point. This point is fixed and the damper moves slightly fore and aft with the movement of the swinging lever. How do I fix this point, so I only get the movement of the damper and the fore aft movement connected to the swinging lever. The texture mapping is done, and VC is on it's way.

Hi Milton,

Thanks for you input and your tutorials, they are much appreciated. Gmax is great once you get more insight. I have been going trough your gear animation series, and I have done some test runs on basic gear animation. It works

However the Falcon 20 gear is slightly different. I just wondered if I could get som input on the damper pivot point. This point is fixed and the damper moves slightly fore and aft with the movement of the swinging lever. How do I fix this point, so I only get the movement of the damper and the fore aft movement connected to the swinging lever. The texture mapping is done, and VC is on it's way.

Attachments

I assume the front parts are treated like an upper strut.

Everything there is linked top down.

The "oleo swing arm" is linked to that.

The axle (tire/wheel) is linked to the swing arm.

The damper is linked the the axle or swing arm.

The damper pivot needs to be moved the the bottom attach point.

It should be animated for up/down and slight rotation fore/aft.

The upper (fat) part of the damper needs to be separated from the oleo.

It needs to be linked to the top horizontal part that rotates during retraction/extension.

The oleo needs to recede into that top part under weight.

The top part needs to be animated to stay in line with the oleo.

My opinion not knowing exactly how all the movement works.

Everything there is linked top down.

The "oleo swing arm" is linked to that.

The axle (tire/wheel) is linked to the swing arm.

The damper is linked the the axle or swing arm.

The damper pivot needs to be moved the the bottom attach point.

It should be animated for up/down and slight rotation fore/aft.

The upper (fat) part of the damper needs to be separated from the oleo.

It needs to be linked to the top horizontal part that rotates during retraction/extension.

The oleo needs to recede into that top part under weight.

The top part needs to be animated to stay in line with the oleo.

My opinion not knowing exactly how all the movement works.

Thnaks. Almost like the "Dry Bones Song" then

I Will try this out tomorrow. Would you normally do the same process for each main gear, or will mirroring work?

Thank you!

I Will try this out tomorrow. Would you normally do the same process for each main gear, or will mirroring work?

Thank you!

I assume the front parts are treated like an upper strut.

Everything there is linked top down.

The "oleo swing arm" is linked to that.

The axle (tire/wheel) is linked to the swing arm.

The damper is linked the the axle or swing arm.

The damper pivot needs to be moved the the bottom attach point.

It should be animated for up/down and slight rotation fore/aft.

The upper (fat) part of the damper needs to be separated from the oleo.

It needs to be linked to the top horizontal part that rotates during retraction/extension.

The oleo needs to recede into that top part under weight.

The top part needs to be animated to stay in line with the oleo.

My opinion not knowing exactly how all the movement works.

Thnaks. Almost like the "Dry Bones Song" then

I Will try this out tomorrow. Would you normally do the same process for each main gear, or will mirroring work?

Thank you!

I usually mirror the parts IF they are not symmetrical. Your parts are likely the same (symmetrical left and right). If so, mirroring is unnecessary.

You can clone as a group.

Then using the part at the top of the hierarchy, relocate the package to the other side.

If not symmetrically vertical or same left to right, only then must you mirror.

If that is the case:

Then, go to the original side, and record the Move Local coordinates, and the Rotate Local coordinates for each animated part.

Use the Move coordinates to reset the Local pivots of the new side parts. (Affect Pivot Only)

Then use the rotation pivot coordinates to reset those pivots.

For parts not symmetrical, you may have to flip the coordinate pivot signs (+ or -).

Test

Thank you, I will test to see what works best.

I usually mirror the parts IF they are not symmetrical. Your parts are likely the same (symmetrical left and right). If so, mirroring is unnecessary.

You can clone as a group.

Then using the part at the top of the hierarchy, relocate the package to the other side.

If not symmetrically vertical or same left to right, only then must you mirror.

If that is the case:

Then, go to the original side, and record the Move Local coordinates, and the Rotate Local coordinates for each animated part.

Use the Move coordinates to reset the Local pivots of the new side parts. (Affect Pivot Only)

Then use the rotation pivot coordinates to reset those pivots.

For parts not symmetrical, you may have to flip the coordinate pivot signs (+ or -).

Test