warchild

Charter Member

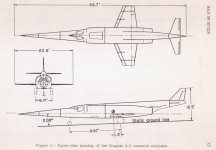

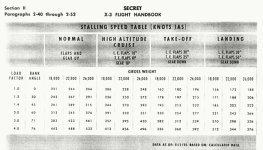

Thanks for the correction and the inclusion of data regarding flaps.. That would have been a hell of a blunder on my part.. It's what I get for pressing calculator buttons way too far past eyelids at half mast in the morning.. I'll be honest. I didnt notice the speed brake in the drawing till after i'd posted it and was looking at uit trying to understand why this patent application only showed le slats and not flaps.. It seemed a bit odd too me. Then i noticed the speed brake and figured at least something good could come out of this as ive never seen a drawing with speed brakes either..

Installed a framework to build this flight model around last night and made some printouts Started looking for engines that could fit in the tiny little spaces they allowed for the engines.. It'll be fun.. Also started pondering ways of making the mean aerodynamic center move backwards during transonic speeds. I think that was the real culprit here as at rest, its already quite far back on the airframe. More study, more learning. I really wish someone was here who could make a pot of coffee. I mean, waking up to no coffee: thats almost inhumane. Its gonna be a long night..

Installed a framework to build this flight model around last night and made some printouts Started looking for engines that could fit in the tiny little spaces they allowed for the engines.. It'll be fun.. Also started pondering ways of making the mean aerodynamic center move backwards during transonic speeds. I think that was the real culprit here as at rest, its already quite far back on the airframe. More study, more learning. I really wish someone was here who could make a pot of coffee. I mean, waking up to no coffee: thats almost inhumane. Its gonna be a long night..