aleatorylamp

Charter Member

Hello Ivan,

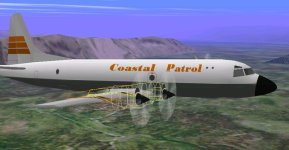

It does not look like there are too many bleeds... but one would need a few more viewing angles to establish that.

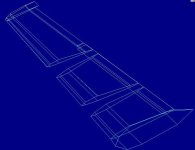

Is it your intention to make a 3-sectioned component for the wing?

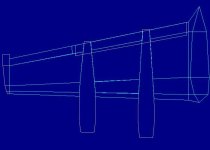

Another question I would like to ask is if it is only spinners+props in Nose left/right, or also the forward nacelle sections,these being divided by the Nose/Wing left/right Templates from whatever is in the wing.

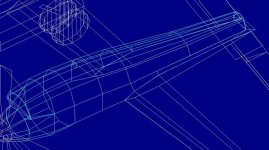

Anyway, I have applied the top outline using your very useful templates from your earllier-on e-mailed Orion to establish the correct nacelle cutouts for the wings (my nacelles were too wide from the leading edge to the exhaust), and I also applied the Wing-twist (longitudinal torsion?), as the new Nacelle side view didn´t match the slope. Now, with a positive angle of incidence inboard, the Nacelle slope towards the trailing edge coincides nicely.

I had to put lots of guide-lines along the wing reminicent of a Bricklayer´s strings to get the parts for the 3 wing components all lined up.

I didn´t put in an extra wing-part in the flat zone ahead of the ailerons and flaps because I have to save the parts for the time being, as I want (for the moment) to keep the animated surfaces.

What´s pleasing is that finally all wing-things are correctly placed! Next come the actual bodies of the nacelles.

Cheers,

Aleatorylamp

It does not look like there are too many bleeds... but one would need a few more viewing angles to establish that.

Is it your intention to make a 3-sectioned component for the wing?

Another question I would like to ask is if it is only spinners+props in Nose left/right, or also the forward nacelle sections,these being divided by the Nose/Wing left/right Templates from whatever is in the wing.

Anyway, I have applied the top outline using your very useful templates from your earllier-on e-mailed Orion to establish the correct nacelle cutouts for the wings (my nacelles were too wide from the leading edge to the exhaust), and I also applied the Wing-twist (longitudinal torsion?), as the new Nacelle side view didn´t match the slope. Now, with a positive angle of incidence inboard, the Nacelle slope towards the trailing edge coincides nicely.

I had to put lots of guide-lines along the wing reminicent of a Bricklayer´s strings to get the parts for the 3 wing components all lined up.

I didn´t put in an extra wing-part in the flat zone ahead of the ailerons and flaps because I have to save the parts for the time being, as I want (for the moment) to keep the animated surfaces.

What´s pleasing is that finally all wing-things are correctly placed! Next come the actual bodies of the nacelles.

Cheers,

Aleatorylamp