Aleatorylamp said:

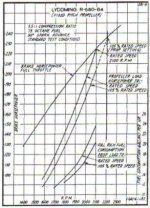

The problem is I can only find the graph for the -B4, an engine similar to the one I´m trying to install, which was the R-680-5 (no letter). For the R-680 "no letter" series there is only a graph for the basic one with 215 Hp available, which is not what I want.

Hello Aleatorylamp,

I believe you are really not understanding the designation system here.

Have you found even ONE military designation that has a prefix letter in it?

As an illustration:

The military called the Continental radial engine the R-670.

The Continental company designation for the same engine was W-670.

The Wright R-1820 engine was used in the B-17, F4F, FM-2, Brewster Buffalo, Curtiss-Wright CW-21, etc.

If the military used it, it had a designation looking like R-1820-SomeNumber.

If it wasn't a military contract, it may have been a simple R-1820-Something OR perhaps a GR-1820-Something.

Company designations used a G prefix if it was a reduction geared engine and no prefix if it was direct drive.

The military never had a G prefix on their models.

There should be a company designation for every military version but it isn't likely to be the same.

Thus your R-680-5 corresponds to some Lycoming R-680 series of engine (I am guessing this is a B series engine).

I am not sure which one matches.

I already hinted at this situation back at Post #42 back on August 15 when I first found the manual you are looking at right now.

-------

It also sounds to me like you are giving up on trying to figure out how this engine should work.

Important thing here is NEVER GIVE UP!

Get it wrong perhaps. Put it on hold until you figure things out, but NEVER GIVE UP!

As I see it, (and I may be wrong because I haven't actually worked on it), the problem you have here is actually very simple to solve. I have been trying to hint at the process without just telling you outright because I thought it would be more meaningful if you figured it out on your own.

First of all, tune your Engine power curves using a Constant Speed Propeller. (Sound Familiar?)

Tuning the Engine:

Plot Horsepower versus RPM. (You already have such a graph in the manual, but you want to make your Engine match it.

Here are some numbers without checking the references, so you will need to check them yourself.

Continuous operation appears to be 1900 RPM giving 202 HP at FULL THROTTLE

Set your test Engine's down to 1900 RPM at FULL THROTTLE and see what the output is. Adjust if needed.

Normal Maximum appears to be 2100 RPM giving 225 HP at FULL THROTTLE

Set your test Engine's down to 2100 RPM at FULL THROTTLE and see what the output is. Adjust if needed.

Absolute Maximum appears to be 2200 RPM giving 237 HP at FULL THROTTLE

Set your test Engine's down to 2200 RPM at FULL THROTTLE and see what the output is. Adjust if needed.

I am thinking your question right now is:

Hey! Wait a minute, what SHOULD the RPM limit be???

Answer: It really doesn't matter because we are tuning the Engine's Torque and Friction curves and you will find that when you finally plug in the fixed pitch propeller, the RPM limit is pretty much meaningless anyway though I still think you should set it to something like 2200 RPM in the final version to make things look right.

Now if you want to control the power with an over speeding propeller, you MIGHT want to tune the Torque or Friction way high above 2200 RPM to discourage High RPM operation. Your call on this one, but I would do it.

Tuning the Propeller:

With your neat nifty Wooden Propeller in place. (Set to Fixed Pitch with proper Angle.)

Adjust your AIR file so that the Aeroplane simply will not move. (This is an Engine / Propeller Bench Test, so bolt it down!)

Put in some Concrete Spoilers, or whatever.

Run your Engine at FULL THROTTLE.

Note the RPM.

Compare the RPM to the specifications in the FAA Type Certification document.

(I TOLD YOU that document was useful!)

Adjust Propeller Power Coefficient in Table 512 until you get proper RPM.

Adjust the rest of the Power Coefficient curve (singular) in Table 512 until you get something looking like other Power Coefficient curves of which you have many examples.

Note that the important parts are basically the two ends at J=0 and where Efficiency drops to Zero.

The rest can be a straight line or slight curve: Your choice.

When you are finished, Remove the Concrete Spoilers and Unbolt the Aeroplane so that it can actually fly again.

Now here comes the really fun part you were agonizing over:

Keep in mind that I am a 1G pilot with no experience on a Stearman, so beware.

As the new owner of this Stearman, the Pilot should read the manual and limitations (Checklist).

It would say something like Blah Blah, Don't exceed normal maximum 2100 RPM for routine flight.

2200 RPM authorized for Take-Off and Climb only.

Vne 186 MPH..... Blah Blah.

Pilot straps in, says his prayers and starts and warms up the engine.

She taxis to the runway and then what?

Does she use FULL THROTTLE on the Take-Off run?

Yes, because this is a naturally aspirated engine and this is one BIG cotton ball with not a lot of engine power.

(Real aeroplane owners are probably hating me right now,)

Is there any danger of exceeding 2200 RPM?

Probably not because the aeroplane is pretty slow on Take-Off and there is a lot of drag on the propeller (Power Coefficient table).

You will have to confirm whether what I am telling you is true or not. I have NOT built this flight model yet.

Just do not exceed 2200 RPM, but by the time that even gets close, the aeroplane should be off the ground and climbing.

So do we reduce power from FULL THROTTLE in the climb?

Probably not because climb speed is so far below maximum that there should be enough propeller drag to keep RPM below 2200.

Besides, if you look at other manuals, the Climb power setting is typically authorized for 30 minutes or so.

Once settled in level flight after the climb is when FULL THROTTLE may not be appropriate.

Here it is a balance of speed and propeller resistance to see what the actual throttle setting should be to get down to 2100 RPM or 1900 RPM or whatever the Continuous Operation limits are.

You will need to experiment here. I can't predict how things will stack up.

Hope that makes sense.

I wish the Propeller issue I am having with my BV 141B were this easy to resolve.

- Ivan.