Communications

Hello Aleatorylamp,

Actually the issue I noticed that will get me to revisit the Ki 61 Propeller is negative Power Coefficients.

The numbers I am using right now pretty much mimic the stock Propeller Tables in that respect, but with the radical edits to get your Propeller Power Coefficient Table, it occurred to me that this probably was not the right approach.

Free time over the last couple days has been spent reading up on Windmilling Propellers and their effects.

It IS related to the Ki 61 propeller table, but in reality has more to do with working on the twin engine stuff.

If your single engine fighter loses an engine, you WILL go down. It is just a matter of time and angle of how you meet local terrain.

With a twin (and less so with more engines) single engine performance simulation is fairly important and I knew very little about that area until recently.

The next step is to create an experiment that can give better insight into how CFS handles negative Power Coefficient values.

As usual, one "new" idea puts a whole lot more stuff on the task list.

Aleatorylamp said:

Another thing you mentioned, is the speed at which the propeller would come off low pitch.

On one hand, you say that it comes off low 18 pitch very soon after the take-off run, and on the other, low pitch seems to be maintained all the way up to 195 mph. Higher would of course make things messy, as you say.

As often happens, we are seriously miscommunicating again:

When I described changing pitch from 18 degrees just after take-off, I was referring to the original CS propeller.

It would obviously be dependent on the stock Hurricane's Power Coefficient Table that you were using, but since it was matched to your engine by Power Coefficient value similarity, it would imply that 18 degrees allows your engine to reach full RPM just after take-off which is great for a CS propeller but suggests that 18 degrees is too fine of a low pitch value if you ONLY have two angles instead of a whole range in between.

Arriving at this conclusion is not exactly that simple because the advance ratio between the Hurricane and FW 200 are so different, but it is one piece of data that should not be ignored.

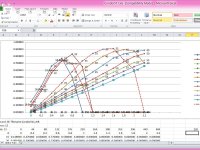

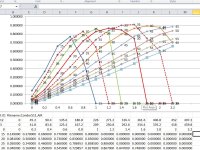

Please Review the attached Screenshot of the Propeller Efficiency Table (511) from the Condor.

Note that I have removed the graphs for 25 degrees and 30 degrees to reduce the clutter and because they were not really relevant to this discussion.

The two pitch values in use are

Red Dash lines.

Note where they cross. That is where we would want a propeller pitch change for optimum performance.

Note the values just above the Advance Ratios. Those are the True Airspeed MPH for each Advance Ratio assuming 2000 RPM.

Note also that the rising slopes and peaks of these efficiency graphs (other than for 25 and 30) are unmodified from the original values used for the Constant Speed Propeller.

One of the big advantage of the CS propeller over the two-pitch is that it can maintain a full 2050 RPM pretty much at any speed above about 100-110 MPH while the two-pitch propeller tends to lug below its optimum airspeed.

Remember I stated that the rising slopes and peaks were unaltered.

Note from the screenshot that 18 degrees and 15 degrees pitch have VERY small advantages over 20 degrees but past J=0.6, their efficiency drops VERY badly and I even raised the efficiency of the 15 degree graph at J=0.8 so that the interpolation for 18 degrees would not be quite so bad.

Aleatorylamp said:

OK, then. Would you think that the default setting of 20 degrees used for fixed pitch propellers would be best?

I remember trying out fixed propellers on the Condor and they seemed to work quite acceptably.

So.... To make a short answer VERY LONG.... a low pitch value of 20 degrees makes a whole lot more sense from an efficiency and geometry standpoint than 18 degrees.

Aleatorylamp said:

P.S. Still another thing you said: While testing, you were getting 719 Hp at 500 ft and 223 mph. That´s fine! I can readily accept that - it´s not really very different from 720 Hp at 300 ft with 226.8 mph.

I told you I was limiting changes to just the propeller tables. That was so we could discuss things from a known common point.

That didn't mean that there were no other problems.

If 719 HP instead of 720 bothers you, adjust it up a touch.... You actually have a lot of room at Sea Level to do this because the Power Coefficient is much much lower than elsewhere.

If the lower speed bothers you, adjust the Coefficient of Drag. If that not precise enough, increase the Oswald Efficiency number to bring it back down again because that number is a bit on the low side anyway.

Aleatorylamp said:

Question: Is it possible to have the same power of 719 Hp at 500ft both with low pitch and relatively low speed, and then ALSO with high pitch at higher speed? I would expect, technically yes...

I don't see why you can't, but I believe the problem here is not so much the power as reaching a consistent RPM and that may be a lot more difficult. That is why I suggested using the torque curve to keep power very similar for the operating range you want (as I did for the Ki 61) and use differences in manifold pressure to control engine output.

This is not unrealistic when compared to the torque graphs from real engines though you have to remember that real engines don't factor out friction into yet another graph when they are being dyno-ed.

- Ivan.