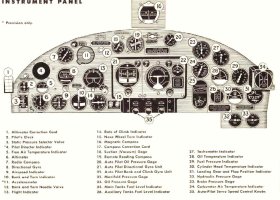

The bitmaps for the gauge took a couple evenings to get to the way I wanted them.

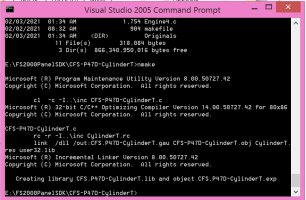

The actual reprogramming took much less than one evening working from the Corsair 500 Knot ASI.

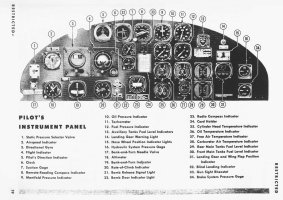

I have tested the gauge and it works, but don't have a good A6M panel as a host. All the panel updates described earlier in this thread have been lost even though the gauges can be reproduced.

I also still have yet to find a current MDL with the latest updates since the initial release in 2013.

- Ivan.

The actual reprogramming took much less than one evening working from the Corsair 500 Knot ASI.

I have tested the gauge and it works, but don't have a good A6M panel as a host. All the panel updates described earlier in this thread have been lost even though the gauges can be reproduced.

I also still have yet to find a current MDL with the latest updates since the initial release in 2013.

- Ivan.