aleatorylamp

Charter Member

Hello folks,

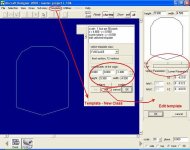

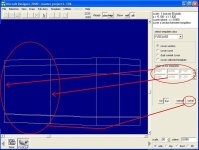

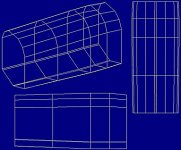

I have been toying with the idea of buiding a Lockheed Electra Model 10, firstly because Smilo suggested building one after I finished practising a bit of AD2K with the two tutorials under his guidance, and secondly, because it would be a good extra opportunity to use Ivan´s interesting new 2-pitch propeller, for a Lockheed Electra Model 10A.

It could also be a good opportunity to build a detailed, fully animated model with AD2K, but only if the "manual Z buffer" sequencing technique could be undertaken by Smilo, as I feel quite incapable of doing something so complicated by myself.

The other possiblility would be to supply a not-so-animated AF99 model, but built as cleanly as possible using building techniques to the best of my knowledge that I have learnt from Ivan, with a SCASMed virtual cockpit, which wouldn´t be bad alternative at all!

So, this project could start with the Lockheed Electra Model 10A as a basis, and then also provide a Model 10E, the one flown by the famous Amelia Earhart. This one had more powerful engines and CV propellers and long range tanks.

The Model 10A was powered by 2 P&W R-985 Wasp Junior SB engines with single-speed superchargers, providing a maximum of 450 Hp at 2300 RPPM for take-off, and giving 400 hp at 2200 RPM upto critical altitude of 5000 ft. Apart from the restly already known but scarce performance specs, I have found an interesting historical article from a flight magazine that quotes a few additional performance details.

Now we know the following:

--------------------------

> Take-off power: 450 Hp at 2300 RPM.

> Lea Level Max Speed: 202 mph.

> Max Speed: 215 mph at 8000 ft.

> Continuous power upto 5000 ft: 400 Hp at 2200 RPM

> General cruise speed: 190 mph

> Cruise speed at 5000 ft: 190 mph at 2000 RPM.

> Max RoC of 1350 fpm (I haven´t tested this yet).

Making the necessary adjustments to the flight model´s engine and airframe parameters, I have arrived at the following results, which are not perfect yet, but would be quite usable, I suppose. Increasing performance a bit for 500 ft, as it isn´t really S.L., would give a bit more at 8000 Ft, at the price of a slight unwanted peak at 5000, because at the moment, 8000 ft performance really happens too soon at 5000 ft...

Maximum speeds:

----------------

_500 ft: 202.0 mph, 450 hp, 2296 RPM

5000 ft: 214.0 mph, 471 hp, 2436 RPM

8000 ft: 207.8 mph, 424 hp, 2412 RPM

Cruise speeds:

_500 ft: 190.9 mph, 399 hp, 2198 RPM, 93% throttle

5000 ft: 190.8 mph, 377 hp, 2410 RPM, 86% throttle

8000 ft: 190.0 mph, 364 hp, 2277 RPM, 85% throttle

Hello Ivan,

I know you are very busy indeed in your paint shop, with the textures on your Ki-61.

Consequently I don´t expect an answer or any comments on these performances, at least not for the moment.

There is time enough for that in the future, if you feel so inclined, so please don´t feel obliged to do so.

Cheers,

Aleatorylamp

I have been toying with the idea of buiding a Lockheed Electra Model 10, firstly because Smilo suggested building one after I finished practising a bit of AD2K with the two tutorials under his guidance, and secondly, because it would be a good extra opportunity to use Ivan´s interesting new 2-pitch propeller, for a Lockheed Electra Model 10A.

It could also be a good opportunity to build a detailed, fully animated model with AD2K, but only if the "manual Z buffer" sequencing technique could be undertaken by Smilo, as I feel quite incapable of doing something so complicated by myself.

The other possiblility would be to supply a not-so-animated AF99 model, but built as cleanly as possible using building techniques to the best of my knowledge that I have learnt from Ivan, with a SCASMed virtual cockpit, which wouldn´t be bad alternative at all!

So, this project could start with the Lockheed Electra Model 10A as a basis, and then also provide a Model 10E, the one flown by the famous Amelia Earhart. This one had more powerful engines and CV propellers and long range tanks.

The Model 10A was powered by 2 P&W R-985 Wasp Junior SB engines with single-speed superchargers, providing a maximum of 450 Hp at 2300 RPPM for take-off, and giving 400 hp at 2200 RPM upto critical altitude of 5000 ft. Apart from the restly already known but scarce performance specs, I have found an interesting historical article from a flight magazine that quotes a few additional performance details.

Now we know the following:

--------------------------

> Take-off power: 450 Hp at 2300 RPM.

> Lea Level Max Speed: 202 mph.

> Max Speed: 215 mph at 8000 ft.

> Continuous power upto 5000 ft: 400 Hp at 2200 RPM

> General cruise speed: 190 mph

> Cruise speed at 5000 ft: 190 mph at 2000 RPM.

> Max RoC of 1350 fpm (I haven´t tested this yet).

Making the necessary adjustments to the flight model´s engine and airframe parameters, I have arrived at the following results, which are not perfect yet, but would be quite usable, I suppose. Increasing performance a bit for 500 ft, as it isn´t really S.L., would give a bit more at 8000 Ft, at the price of a slight unwanted peak at 5000, because at the moment, 8000 ft performance really happens too soon at 5000 ft...

Maximum speeds:

----------------

_500 ft: 202.0 mph, 450 hp, 2296 RPM

5000 ft: 214.0 mph, 471 hp, 2436 RPM

8000 ft: 207.8 mph, 424 hp, 2412 RPM

Cruise speeds:

_500 ft: 190.9 mph, 399 hp, 2198 RPM, 93% throttle

5000 ft: 190.8 mph, 377 hp, 2410 RPM, 86% throttle

8000 ft: 190.0 mph, 364 hp, 2277 RPM, 85% throttle

Hello Ivan,

I know you are very busy indeed in your paint shop, with the textures on your Ki-61.

Consequently I don´t expect an answer or any comments on these performances, at least not for the moment.

There is time enough for that in the future, if you feel so inclined, so please don´t feel obliged to do so.

Cheers,

Aleatorylamp