aleatorylamp

Charter Member

Wing profile shape?

Hello Smilo, hello all!

Making the wingroot, I discovered that there were some adjustments to be made at the bottom of the central-fuselage bulkheads, in order to get correct shapes for the wing-root trailing edge and the fuselage sides. The rudimentaruy central bulkhead drawing had the floor too "V"-shaped.

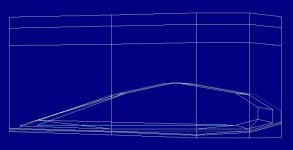

Now, to make the wingroot, AD2K basically offers 2 useful options for the wing profile, both of which are acceptable despite their shortcomings, but none of which offer the exact shape required. Now the problem is to decide which!

The top of the picture shows the required wing-root shape in red: Bi-convex, with a positive angle of incidence.

Below that are the two AD2K possibilities:

The bi-convex profile leaves the trailing edge too high and the simple plano-convex profile leaves the trailing edge too low.

So, what shall it be? We could always have a vote...

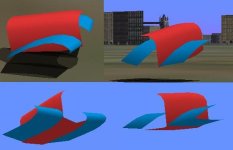

Incidentally, what is a really very cool building option offered in AD2k is the "Intersection", typically used for wing-fuselage joints:

Instead of placing the inside inner-wing profile template flush with the fuselage wall (which can be difficult if curved) and then cover the space upto the outer profile template with panels, the Intersection Option is more automatic: It uses an inner profile template placed within the fuselage, and then covers only the outside surfaces going towards the outer profile template. Very practical!

Cheers,

Aleatorylamp

Hello Smilo, hello all!

Making the wingroot, I discovered that there were some adjustments to be made at the bottom of the central-fuselage bulkheads, in order to get correct shapes for the wing-root trailing edge and the fuselage sides. The rudimentaruy central bulkhead drawing had the floor too "V"-shaped.

Now, to make the wingroot, AD2K basically offers 2 useful options for the wing profile, both of which are acceptable despite their shortcomings, but none of which offer the exact shape required. Now the problem is to decide which!

The top of the picture shows the required wing-root shape in red: Bi-convex, with a positive angle of incidence.

Below that are the two AD2K possibilities:

The bi-convex profile leaves the trailing edge too high and the simple plano-convex profile leaves the trailing edge too low.

So, what shall it be? We could always have a vote...

Incidentally, what is a really very cool building option offered in AD2k is the "Intersection", typically used for wing-fuselage joints:

Instead of placing the inside inner-wing profile template flush with the fuselage wall (which can be difficult if curved) and then cover the space upto the outer profile template with panels, the Intersection Option is more automatic: It uses an inner profile template placed within the fuselage, and then covers only the outside surfaces going towards the outer profile template. Very practical!

Cheers,

Aleatorylamp