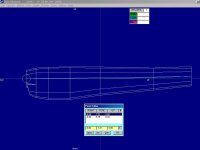

AF99 - Fuselage to Wing Templates

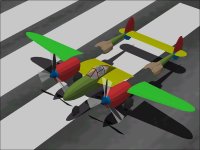

Strictly speaking, this post is not really about a design study of the P-38J Lightning.

It is about the tool that I am using to build the 3D Model and its limitations.

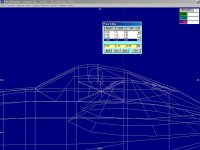

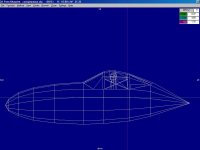

Aircraft Factory 99 has a feature that is described as a Fuselage to Wing Template.

It defines a viewing plane that is not orthogonal to the axes that will be the separation between the Fuselage and say the Left Wing.

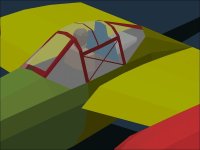

On the P-38, the join between the Nacelle and the Inner Wing section between the Nacelle and Engine is a very odd line. From a plan view, the line begins at the Wing Root at the Leading Edge (about 1.6 Feet from the aircraft centerline) and ends at the tip of the Nacelle ON the aircraft centerline.

This is a natural place to use a Fuselage-Wing Template.

What I found is that the template does not work with the project as built thus far. Neither side works and the behaviour is somewhat odd.

As a quick test, I used only the Inner Wing sections and the Nacelle along with the templates and they worked exactly as expected.

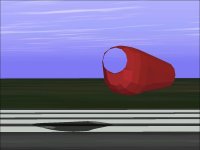

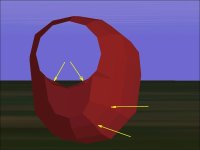

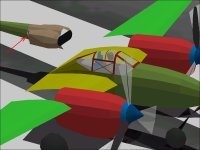

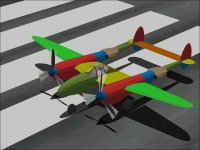

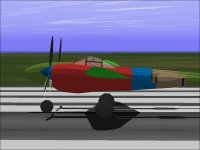

The attached screenshots show the Bleed versus No Bleed from nearly the same angle.

....

Strictly speaking, this post is not really about a design study of the P-38J Lightning.

It is about the tool that I am using to build the 3D Model and its limitations.

Aircraft Factory 99 has a feature that is described as a Fuselage to Wing Template.

It defines a viewing plane that is not orthogonal to the axes that will be the separation between the Fuselage and say the Left Wing.

On the P-38, the join between the Nacelle and the Inner Wing section between the Nacelle and Engine is a very odd line. From a plan view, the line begins at the Wing Root at the Leading Edge (about 1.6 Feet from the aircraft centerline) and ends at the tip of the Nacelle ON the aircraft centerline.

This is a natural place to use a Fuselage-Wing Template.

What I found is that the template does not work with the project as built thus far. Neither side works and the behaviour is somewhat odd.

As a quick test, I used only the Inner Wing sections and the Nacelle along with the templates and they worked exactly as expected.

The attached screenshots show the Bleed versus No Bleed from nearly the same angle.

....

)

)