Finished?

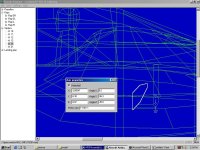

There are small scoops on either side of each cowl which I believe are for spark plug cooling.

They look quite prominent in the current "Sharp" Component but may be much less visible when the Component is made "Smooth" for painting.

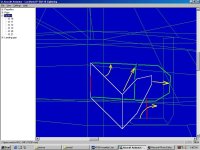

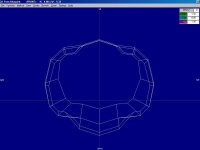

After adding those, the Resource count is as follows:

1195 Parts of 1200 allowed.

197 Separate Parts in the Assembly out of 200 allowed.

30 Components of 30 allowed.

6 Structures of 30 allowed.

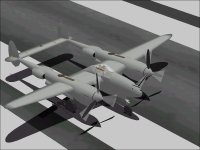

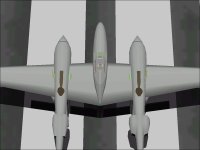

For all practical purposes, the model is as good as I know how to do within AF99 limitations at this point.

Many improvements can be done within SCASM, but the purpose here was to build at least the exterior model entirely within AF99 limits.

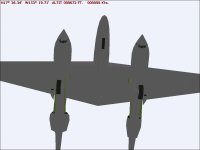

There is still quite a lot of experimentation that can be done with the Fuselage to Wing Templates which I intend to do.

Next step with this model is animation of the current assembly.

- Ivan.

There are small scoops on either side of each cowl which I believe are for spark plug cooling.

They look quite prominent in the current "Sharp" Component but may be much less visible when the Component is made "Smooth" for painting.

After adding those, the Resource count is as follows:

1195 Parts of 1200 allowed.

197 Separate Parts in the Assembly out of 200 allowed.

30 Components of 30 allowed.

6 Structures of 30 allowed.

For all practical purposes, the model is as good as I know how to do within AF99 limitations at this point.

Many improvements can be done within SCASM, but the purpose here was to build at least the exterior model entirely within AF99 limits.

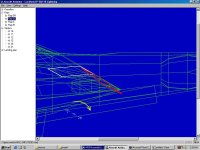

There is still quite a lot of experimentation that can be done with the Fuselage to Wing Templates which I intend to do.

Next step with this model is animation of the current assembly.

- Ivan.