Hello Aleatorylamp,

This is another one of those situations in which a LOT could be explained visually over a long lunch meeting but it is hard to do this via words in a forum post. Let's try anyway....

Aleatorylamp said:

The assembly sequence within the engine component appears to be crucial for complex components. I remember you saying so before, but from there to understand how a logical placement would run, is another matter. Thus, concave areas between cylinders don´t disappear because parts order is listed inversly to the visibility priority.

You are about half correct in your paragraph:

Component assembly order is crucial - True.

Concave areas don't disappear - Whether concave areas disappear has nothing to do with assembly order.

Explanation:

Aircraft Factory 99 is either too stupid or too smart for its own good.

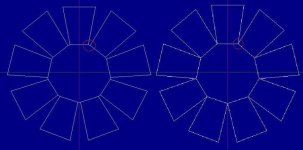

A COMPONENT has a "Central Point" or "Center of Gravity" which is calculated from the polygons or vertices from which it is comprised. I have my theories as to how this Central Point (CP) is calculated but won't get into details here because my ideas are not so rigorous yet.

Each polygon of the Component can have a ray drawn from the CP to its center which then determines the facing of the polygon: All polygons face Outward.

If Smilo is reading along, he is probably thinking AD 2000 does it in a much smarter way by the order of the vertices and he is right. That IS the smarter way, but it leaves the task up to the aircraft designer.

Thus assuming that the CP is in the exact center of your motor Component, a cylinder wall will continue to display until its inclination becomes so steep that it crosses the center axis. I was pretty sure you were not going to do that which is why I told you that putting a flare / taper into the cylinder would not cause any additional bleeds.

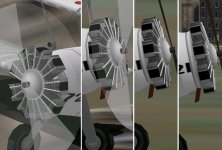

The ORDERING SEQUENCE within the Component is what determines bleeds. All I really did to your motor Component was to adjust the order of Parts. I renamed everything because I didn't want to do math to figure out which piece I needed to find next in the sequence.

You have a couple of my AFXs, so look closely at how I name and number the Parts. It is boring but makes it really easy to locate where something is supposed to be. Sometimes the numbering looks odd but usually that is because the Parts are numbered in the order that they need to be added. This saves time when there is a need to rebuild a Component inside AF99.

My early projects were not so well organised and were a lot more confusing to follow.

As I commented earlier, none of the Parts would disappear regardless of the ordering.

The ordering is done so that the Parts which are highest visual priority (never covered by anything else) are listed last, followed by the ones of lesser priority and so on.

That is the "big secret" not that I ever intended it to be a secret.

In fact, there are still bleeds in the motor Component. Some of the cylinder walls are bleeding through others but that is impossible to avoid. I just ordered things so that the bleeds are hidden as much as possible.

Aleatorylamp said:

The thing is, the square shaped area in where the engine sits on the model is covered by a rectangular 256x128 bitmap, so cylinders must not only be rotated by a given angle starting with number 1, but also stretched sideways depending on their position.

Why are you using a 265 x 128 texture when it would look the same with a 128 x 128 texture and be much easier to draw?

Aleatorylamp said:

Can you believe that with all the engine tuning confusion, I got the correct Continental engine performance with the wrong engine?!!: I ended up using the Lycoming 9x75.55 cu.in. with 5.5:1 compression ratio instead of the Continental 7x95.44 cu. in. with 5.4:1.

Sounds like pretty good proof that these two engines were not that far apart in performance and that if something works for one of them, it works for the other.

There are obviously other design characteristics that make it possible to hotrod the Lycoming but not the Continental engines.

- Ivan.