Merlin Power

Now that I have a pretty reasonable P-40E as a starting point, the Conversion / Duplication Process for the Merlin powered P-40F begins.

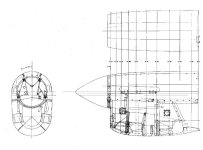

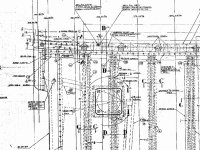

This model will be a bit more difficult because the scans of the Factory Drawings for the F-model Cowl section is much worse quality and appears to have some distortions.

There are also some disagreements in dimensions between the various models:

The P-40E as modeled is 31 feet 8.75 inch or 31.73 feet in AF99 units.

The length varies a bit depending on the source. The most plausible dimensions are 31 feet 8 inch to 31 feet 9 inch with 31 feet 8.75 inch being the most likely value in my opinion.

The length of the P-40F also has a similar variation ranging from 31 feet 7 9/16 inch to 31 feet 7.75 inch depending on the aircraft manual. The variation is actually much higher than this from sources other than the manuals.

The Datum Point as stated earlier is at Station 1 (The Firewall) longitudinally and at the Fuselage Reference Line vertically.

The Forward End of the Cowl is 87.0 inches ahead of the Datum for most Hawk 87 models.

For the Hawk 87D (Merlin Powered) P-40F / P-40L, the End of the Cowl is only 85.75 inches ahead of the Datum.

The Merlin was a heavier engine than the Allison and I believe the difference in engine location was to maintain a consistent CoG without having to add ballast.

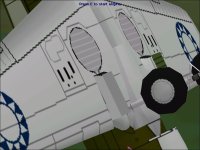

Another feature worthy of note is that the forward edge of the Cowl had a slight bevel and the Spinner actually overlapped the Cowl slightly. The visible gap that is in my model is really just a line on the real aeroplane.

When I scaled the Factory Drawing of the F-model Cowl to match the 85.75 inch (7.1458 or 7.15 feet) dimension, I found that the top of the Cowl did not quite match the other drawings and the length of the Spinner was about 1/2 inch too short as compared to the E-model Spinner.

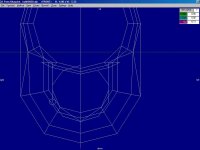

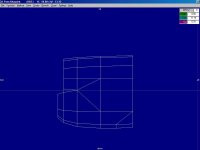

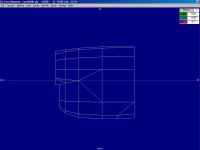

Now comes the fun part of measuring offsets for the new 3D model.

(The CoG of the model remains at 2.35 feet Aft and 0.55 feet Below the Aircraft Datum Point.)

- Ivan.

Now that I have a pretty reasonable P-40E as a starting point, the Conversion / Duplication Process for the Merlin powered P-40F begins.

This model will be a bit more difficult because the scans of the Factory Drawings for the F-model Cowl section is much worse quality and appears to have some distortions.

There are also some disagreements in dimensions between the various models:

The P-40E as modeled is 31 feet 8.75 inch or 31.73 feet in AF99 units.

The length varies a bit depending on the source. The most plausible dimensions are 31 feet 8 inch to 31 feet 9 inch with 31 feet 8.75 inch being the most likely value in my opinion.

The length of the P-40F also has a similar variation ranging from 31 feet 7 9/16 inch to 31 feet 7.75 inch depending on the aircraft manual. The variation is actually much higher than this from sources other than the manuals.

The Datum Point as stated earlier is at Station 1 (The Firewall) longitudinally and at the Fuselage Reference Line vertically.

The Forward End of the Cowl is 87.0 inches ahead of the Datum for most Hawk 87 models.

For the Hawk 87D (Merlin Powered) P-40F / P-40L, the End of the Cowl is only 85.75 inches ahead of the Datum.

The Merlin was a heavier engine than the Allison and I believe the difference in engine location was to maintain a consistent CoG without having to add ballast.

Another feature worthy of note is that the forward edge of the Cowl had a slight bevel and the Spinner actually overlapped the Cowl slightly. The visible gap that is in my model is really just a line on the real aeroplane.

When I scaled the Factory Drawing of the F-model Cowl to match the 85.75 inch (7.1458 or 7.15 feet) dimension, I found that the top of the Cowl did not quite match the other drawings and the length of the Spinner was about 1/2 inch too short as compared to the E-model Spinner.

Now comes the fun part of measuring offsets for the new 3D model.

(The CoG of the model remains at 2.35 feet Aft and 0.55 feet Below the Aircraft Datum Point.)

- Ivan.