aleatorylamp

Charter Member

Hello Ivan, Hello Ivan,

Ivan, I hope your son´s grades will reflect the effort that has gone into preparing him for his tests. Good Luck!

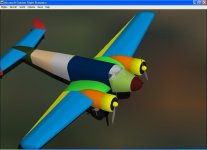

Right now I´m trying my luck at the metallic textures, adapting, changing and fitting some existing ones. Most of the plane is textured now - at least provisionally.

I also got the crew in, with a rather complicated glue sequence that also involved the nose, the roof and the windows, apart from the cabin body, back and floor. But it worked!

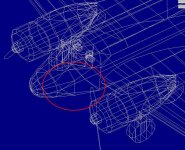

What was really difficult was the windscreen and the cabin roof shape, and also the nacelle shapes with relation to the wing.

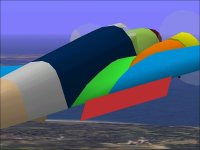

The fuselage in this case has no structures - it´s all components except for the nose. The engine nacelle structures are now 12-sided. Fins and wheels are also structures, and now parts count is still at a modest 129%. Perhaps adding parts with SCASM won´t be necessary this time.

With the available power, I suppose it´s difficult to get this kind of plane any faster.

This Electra 10A does 202 mph top speed, with 2 x 450 Hp engines and a 55 ft wingspan.

The similar Beechcraft 18 with the same engines and 7 ft less wingspan, did 225 mph.

Amelia Earhart´s Electra Model 10E had 2 x 600 Hp, so it must have been a bit faster.

Remember the Curtiss Fledgling? That one only did 197 mph, but had less power with its 2 x 300 hp engines, but compensated for it with its shorter 31.8 ft wingspan.

Well... I still have to add the tail-wheel strut, and generally clean up the build, get rid of cracks and so on, so it´ll be a while yet until it´s ready - but of course, there´s no hurry!

Anyhow, here´s a bit more eye candy, Smilo! The tucked-in wheels, visible when retracted, are also on now.

Cheers,

Aleatorylamp

Ivan, I hope your son´s grades will reflect the effort that has gone into preparing him for his tests. Good Luck!

Right now I´m trying my luck at the metallic textures, adapting, changing and fitting some existing ones. Most of the plane is textured now - at least provisionally.

I also got the crew in, with a rather complicated glue sequence that also involved the nose, the roof and the windows, apart from the cabin body, back and floor. But it worked!

What was really difficult was the windscreen and the cabin roof shape, and also the nacelle shapes with relation to the wing.

The fuselage in this case has no structures - it´s all components except for the nose. The engine nacelle structures are now 12-sided. Fins and wheels are also structures, and now parts count is still at a modest 129%. Perhaps adding parts with SCASM won´t be necessary this time.

With the available power, I suppose it´s difficult to get this kind of plane any faster.

This Electra 10A does 202 mph top speed, with 2 x 450 Hp engines and a 55 ft wingspan.

The similar Beechcraft 18 with the same engines and 7 ft less wingspan, did 225 mph.

Amelia Earhart´s Electra Model 10E had 2 x 600 Hp, so it must have been a bit faster.

Remember the Curtiss Fledgling? That one only did 197 mph, but had less power with its 2 x 300 hp engines, but compensated for it with its shorter 31.8 ft wingspan.

Well... I still have to add the tail-wheel strut, and generally clean up the build, get rid of cracks and so on, so it´ll be a while yet until it´s ready - but of course, there´s no hurry!

Anyhow, here´s a bit more eye candy, Smilo! The tucked-in wheels, visible when retracted, are also on now.

Cheers,

Aleatorylamp